ALLES Product Certification

ALLES CNC Machine have passed CE from TÜV,ROHS,FDA,ETL certificates, which is in line with European and American standards.

“ALLES CNC will never tire of sharing China ’s excellent, high-quality, high-end, high-quality equipment and machine tools, sharing the world, letting everyone share high-quality, competitive-price industry machine tools, sharing technological progress, building an industrial system, and improving the good life together” Quality policy and goals. SHANDONG ALLES ENERGY TECHNOLOGY CO., LTD, as China's star CNC machine manufacturer, solves and meets customer requirements with higher than international and domestic standards, establishes an internal quality assurance system, implements comprehensive and full-process quality management, and effectively controls the process Is the core to ensure product quality and improve product quality.

SHANDONG ALLES ENERGY TECHNOLOGY CO., LTD strictly controls the quality of machine tool production and has obtained a number of international quality certifications: ISO9001 quality management authority certification, CE certification for export to the EU, and export licenses.

At the same time, as an outstanding machine tool manufacturer in China, it has obtained nearly 20 patent certificates including utility model certificates and utility model patent certificates. The country gives high honors: national star enterprises, becoming China's TOP10 outstanding enterprises.

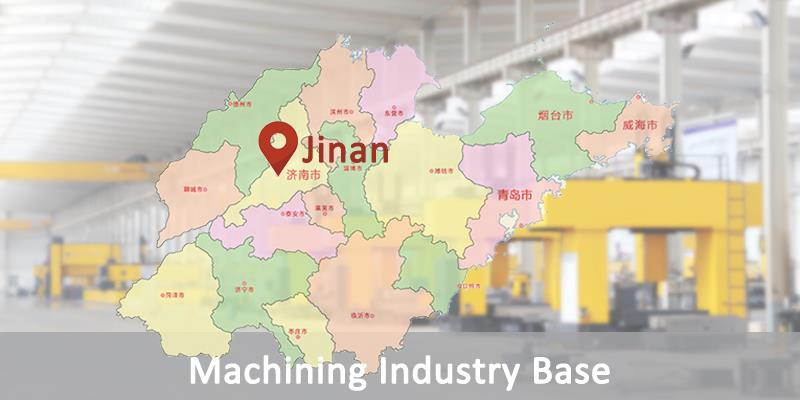

The factory of SHANDONG ALLES ENERGY TECHNOLOGY CO., LTD is located in Zhangqiu, Jinan City, Shandong Province, China. Shandong is China's heavy industry processing center, including iron and steel industry, metallurgical industry, machinery, energy (electricity, petroleum, coal, natural gas, etc.), chemical, materials and other industries. It is a base for forging and casting. And Zhangqiu Shandong is a machining industry base with more than 1,000 machinery manufacturing enterprises, including various types of machinery and various types of mechanical parts, which can timely fill the shortage of parts and complete customer requirements in a timely manner. Therefore, ALLES has a complete industrial chain and formed a product system with high quality and low price.

ALLES has sufficient storage capacity, including 3 warehouses. The warehouse has a large number of spare parts and stocks. All parts and accessories of the machine tool are fully stocked and sourced. More than 350 employees guarantee the assembly of the machine. Each link and process can be completed with quality and quantity, and the customer's delivery date is completed as soon as possible.

ALLES has complete machining equipment and quality control system to ensure assembly accuracy and machine supply requirements.

Up to 300 machining equipment are used to ensure the production requirements of machine tool accessories, including CNC lathe machine, CNC drilling machine, CNC grinding machine, CNC boring and milling machine and other CNC machine tools. High efficiency and high precision machining.

一切数控追求先进的科研侦探hnology and strict quality control. It adopts a variety of testing equipment such as the Leader brand of the United States, the American Renishaw Laser Interferometer, the balancer, and the tool setter to perform strict quality control on all aspects of machine tool production. Keep improving, make customers' processing more stable and efficient.

1.Three coordinate measuring instrument

The three-axis coordinate measuring instrument has a gas source brake switch and a microwave device, which can realize single-axis transmission. The data acquisition system uses a high-performance manual three-axis dedicated system with good reliability.

Scope of application: product design, mold equipment, gear measurement, blade measurement machinery manufacturing, tooling fixtures, auto parts, electronic appliances, etc.

2.Tool setting instrument

During the processing of the workpiece, auxiliary time such as workpiece loading and unloading and tool adjustment account for a considerable proportion of the processing cycle. Among them, the adjustment of the tool is laborious and time-consuming, and it is not easy to be accurate. Finally, trial cutting is required.

3.Balance

With data acquisition, spectrum analysis and other functions, it can enable users to accurately determine whether balance is a problem. It can effectively report the reliability and safety of obstacle equipment operation, and can obtain good economic and social benefits, which has great practical significance.

4.Renishaw laser interferometer

Using the laser wavelength as a known length, the interference system is used to measure the universal length of the displacement. It has the advantages of high strength, high directivity, and spatial coherence.

In the assembly process of ALLES CNC, from design to production, from picking to assembly, from inspection to qualified storage, we have formulated very detailed and strict control processes at each working stage to ensure that each machine and every link Every step is done well.

ALLES has a stable after-sales service team that is proactive, fast and effective. There is a 24-hour telephone online service, which will respond within 2 hours after receiving the user's notification. Have a high-skilled, high-quality installation and commissioning team. Before the machine tool is shipped, we proactively provide the customer with the bill of materials that the customer needs to prepare when the machine tool is installed, and meet the customer's needs in a timely manner. Installation and commissioning services for ALLES machine tools are provided free of charge. After installation, the customer's operators are trained on how to use the machine tools correctly. Regular visits will be conducted to understand the operation of customers and the use of machine tools.